¶ Underload Settings

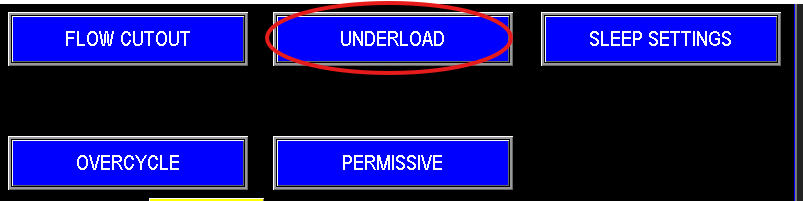

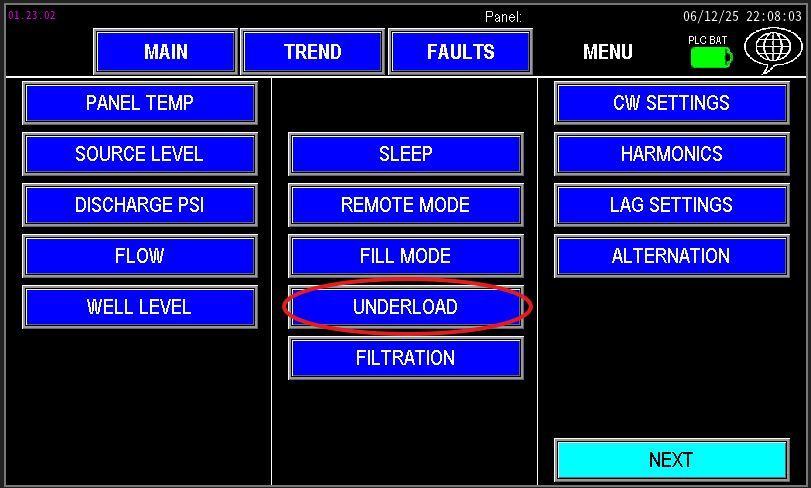

The Underload setting, accessible via the pump menu settings (Image 1.1) or through the menu screens (Image 1.2), enables monitoring of discrepancies between pump frequency and torque, indicating insufficient water in the pump. This could mean the pump is running dry or not receiving adequate water on the intake side. Familiarize yourself with these settings in the Omnia Manual to ensure proper configuration and effective pump operation.

|

|

¶ Jockey Underload

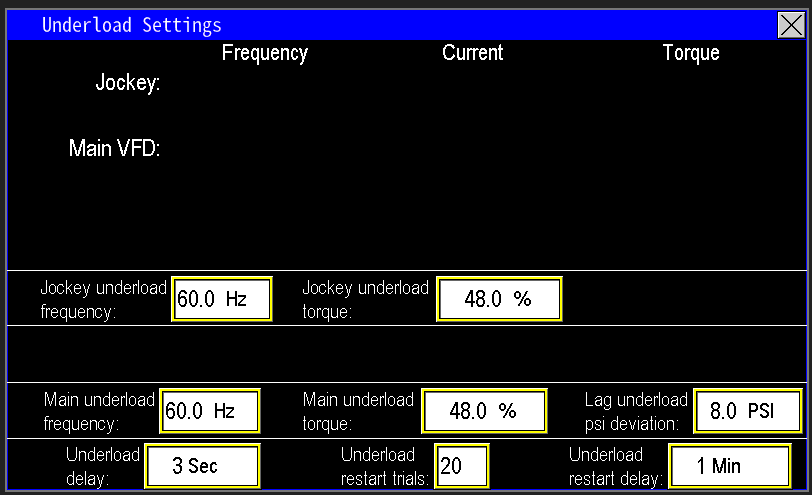

At the top of screen 1.3, shows the current motor data readings the PLC is receiving from the drive. Those readings are Frequency, current, kW, and torque.

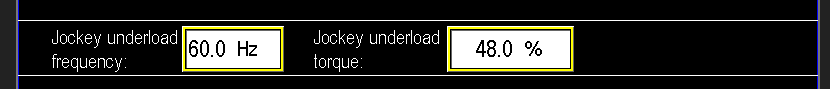

In the scenario depicted in Image 1.4, if the Jockey pump operates at 60 Hz with a torque at or below 48%, the PLC will trigger an underload fault for the pump. Image 1.5 displays the underload settings applicable to all pumps in the station. The Underload Delay represents the time between when the PLC detects an underload condition and when it faults the station. Setting this delay as low as possible, without causing false faults, is critical to minimize wear and tear on the pump head.

When a pump faults on underload, the PLC initiates an Underload Restart Delay, which determines how long the pump remains faulted before automatically resetting. As shown in Image 1.5, this delay is set to 1 minute but is configurable. If the underload condition persists and the pump faults again, the system will attempt to restart the pump up to 20 times. Should the pump continue to fault after these 20 attempts, it will not restart automatically. At this point, manual intervention at the station is required to diagnose and resolve the issue before operations can resume. Refer to the Omnia Manual for detailed troubleshooting and configuration guidance.

¶ Main Pump Underload

The underload functionality for the main pumps operates similarly to the Jockey pump, with the same variables and conditions as described in the previous section. For pumps equipped with a variable frequency drive (VFD), the underload settings are consistent, though setpoints may vary slightly. However, if a main pump lacks a VFD, detecting underload becomes more challenging and is not an adjustable setting without a drive configured.

When a panel is configured to run only the Lead pump with a drive and the rest of the pumps get straight power, Omnia includes a Lag Underload PSI Deviation setting for pumps not controlled by a VFD. Without a drive, the PLC cannot directly monitor motor performance, as it typically relies on drive parameters for this data. Instead, the PLC monitors PSI deviation. If the pump station’s pressure deviates beyond the set Lag Underload PSI Deviation threshold for longer than the Underload Delay, the lag pump will fault on underload. In the example below (image 1.6) the PI threshold is 8psi. This mechanism allows the PLC to protect non-VFD pumps from issues like seal damage or pump failure.

¶ Pumps

For more specific settings pertaining to a particular pump click one of the pump links below: