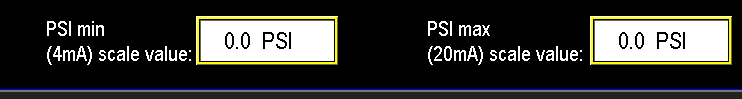

¶ Recirc Pump Pressure Settings

Recirc Pressure settings (image 1.1) govern the pressure used specifically for controlling the speed of the Recirc pump. These settings apply only to the recirc pressure transmitter and are independent of the other pressure transmitters that control the pump station.

¶ Current Pressure

The Current Pressure value on this screen relates exclusively to the recirculation pump connected to the pump station panel — not the station discharge transmitters (image 1.2). Typically, the recirc pump operates at low pressure with higher flow (e.g., maintaining circulation or powering a water feature). The recirc pressure transmitter controls only the recirc pump speed and does not affect the operation of the station’s other pumps.

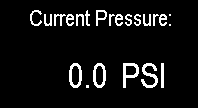

¶ Low Pressure fault limit and delay

Recirc pump protection uses two parameters: Low Pressure Fault Limit and Low Pressure Delay (image 1.3).

- Low Pressure Fault Limit: the minimum acceptable recirc pressure.

- Low Pressure Delay: the time the pressure must remain below the limit before a fault is declared.

If the recirc pressure falls below the fault limit, the delay timer starts. If the condition persists until the timer elapses, the recirc circuit faults to protect the pump. If pressure recovers before the delay completes, the timer resets and the pump continues normal operation.

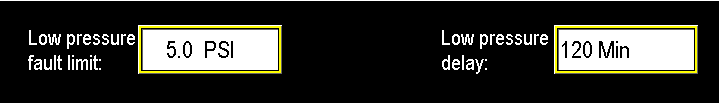

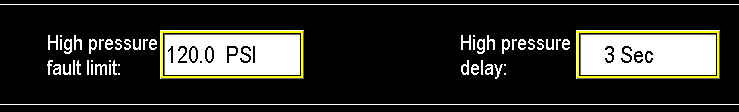

¶ High Pressure fault limit and delay

The Recirc high-pressure protection mirrors the low-pressure configuration but uses a much shorter fault delay—typically a few seconds—to protect system components (image 1.4). Set the high-pressure limit at or below the lowest maximum-rated PSI of system components to prevent damage. When the recirc pressure exceeds this limit, the recirc circuit will fault and shut down immediately. This fault applies only to the recirc pump; it does not fault the main station.

¶ Transmitter scaling

To ensure accurate readings, set the Pressure Max (20 mA) field to match the transmitter’s maximum range (image 1.5). At the transmitter, note the device’s maximum pressure span and enter that value into the Pressure Max (20 mA) scale value on the screen. This ensures the PLC/SCADA displays correct recirc pressure readings.