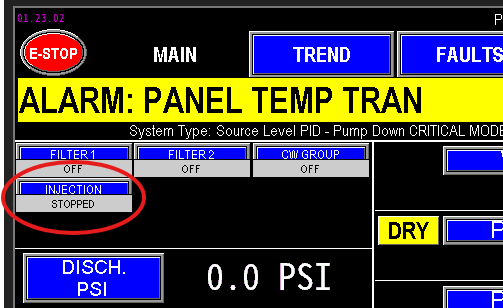

¶ Injection Valves

Injection valves are essential components added to stations that introduce chemicals or other substances into the water flow during pumping. These valves work alongside the injection pump to precisely control the amount and timing of the substance being added, ensuring consistent and effective dosing for water treatment or other operational requirements.

¶ Pump Injector Valve Settings

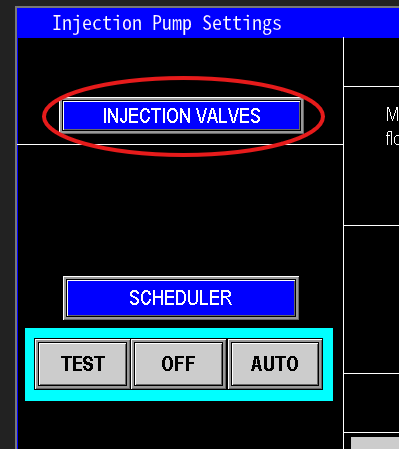

To access the Injector Valve settings:

- Start from the main screen (Image 1.2), and enter the Injector Pump settings.

- Within the Injector Pump menu, click on "Injection Valves" (Image 1.3).

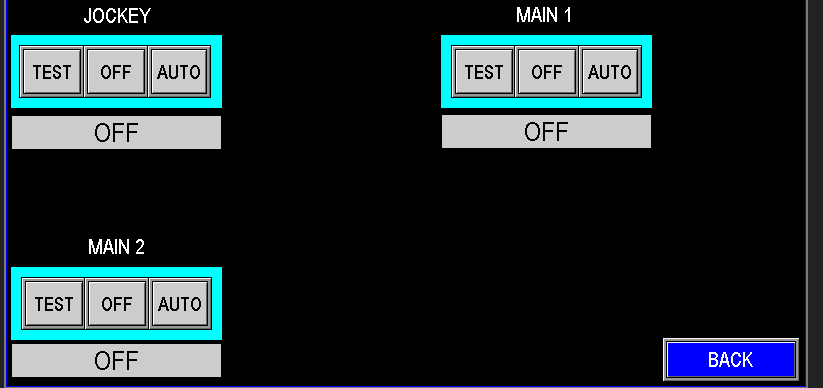

This will take you to the Injector Valve configuration screen (Image 1.1), where you can set up and adjust the valve parameters.

|

|

|

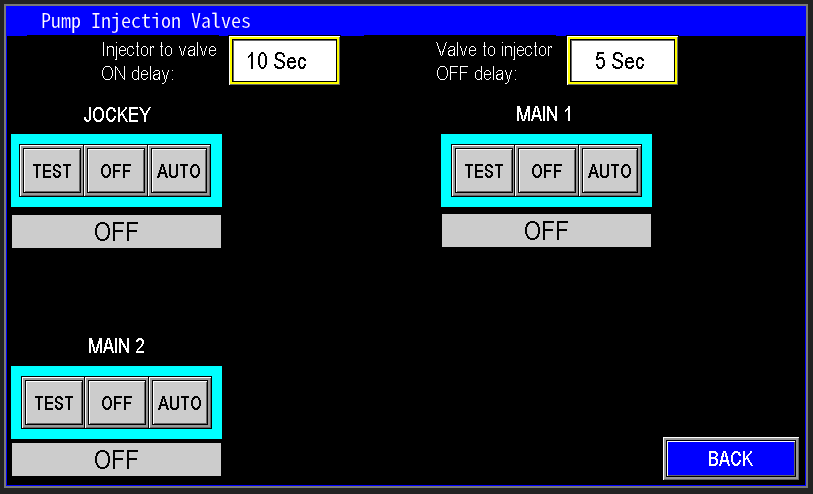

¶ On/Off Delay

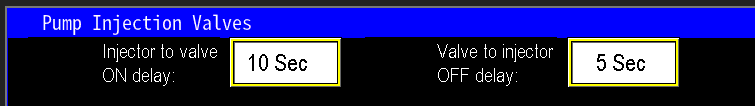

Within the injector valve configuration, two timer delays help ensure proper priming and prevent air pockets in the injection line (Image 1.4):

"Injector to Valve ON Delay":

This timer controls how long the injector pump runs before opening the valve. After the set delay (e.g., 10 seconds), the valve opens, allowing chemical injection into the main line.

"Valve to Injector OFF Delay":

Following the closing of the valve, this timer waits for a specified delay (e.g., 5 seconds) before turning off the injector pump. This ensures the line is fully filled with chemical and prevents gaps in injection.

Example Sequence:

The injector pump starts, waits 10 seconds, then the valve opens and injection begins. When the main system is shutting down or the pumps turn off, the valve closes, waits 5 seconds, and then the injector pump stops. This sequence maintains continuous chemical presence in the line without gaps.

¶ Virtual Operators

The bottom section (image 1.5) displays the virtual operator controls for each injection valve installed on the station:

- "Test": Manually activates the valve, keeping it on until the operator deactivates it or switches the mode.

- "Off": Shows the valve is in its resting state, not being controlled by manual commands or automation.

- "Auto": Enables the PLC-controlled operation, allowing the valve to open and close according to the programmed automation sequence and set parameters.

These controls provide flexible management, allowing manual testing or automatic operation based on system needs.