¶ Fill Mode

When stations start up for the first time or after a power outage, line pressure may be extremely low. Rapidly ramping pump speeds to meet the normal pressure setpoint can stress downstream valves and components, potentially causing damage or delays for repairs.

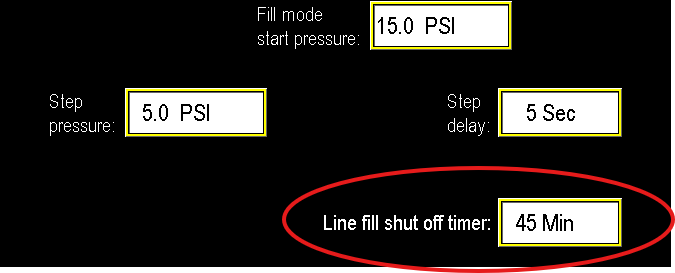

Line Fill Mode mitigates this risk by setting a lower, more gradual pressure setpoint. This allows the pumps to fill the system slowly and safely (Image 1.1), ensuring pressure builds up in a controlled manner and reducing the likelihood of equipment stress or failure during startup.

|

|

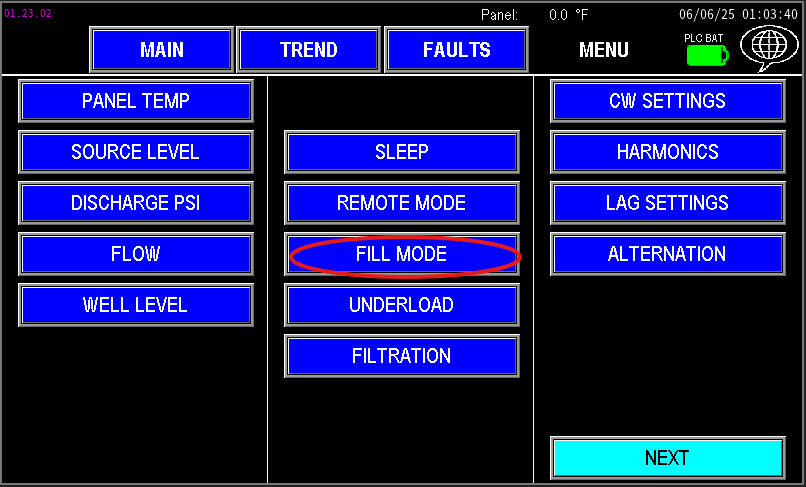

¶ Fill Mode Start Pressure

When fill mode is enabled, the Start Pressure setting determines the pressure threshold at which the system switches into line fill mode to protect downstream components. Setting this value according to station specifications is important for proper operation.

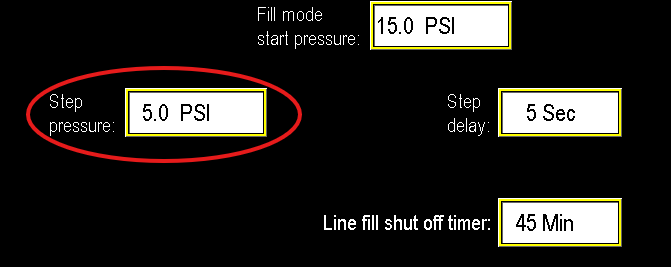

For example, in Image 1.2, the fill mode activates whenever the pressure drops below 15 psi. Once activated, the system scales down the pressure setpoint to a lower value, slowing pump operation to safely fill the system gradually and prevent stress or damage to downstream assets.

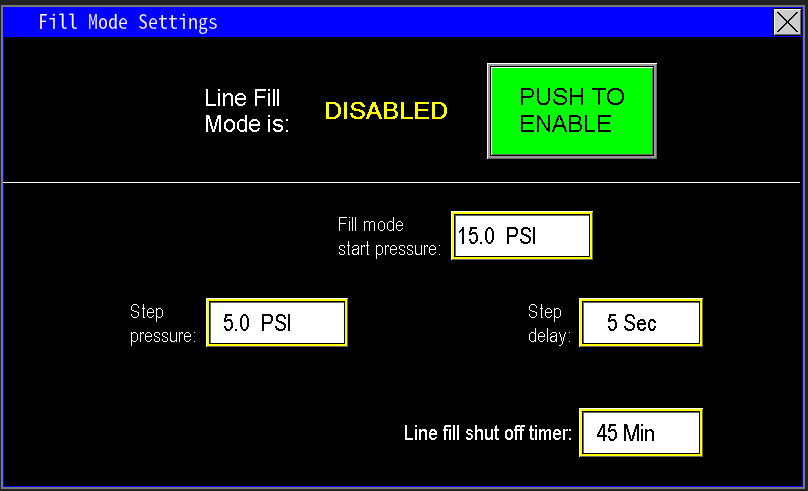

¶ Step pressure

When fill mode is enabled, the Start Pressure setting determines the pressure threshold at which the system switches into line fill mode to protect downstream components. Setting this value according to station specifications is important for proper operation.

For example, in Image 1.3, the fill mode activates whenever the pressure drops below 15 psi. Once activated, the system scales down the pressure setpoint to a lower value, slowing pump operation to safely fill the system gradually and prevent stress or damage to downstream assets.

When in fill mode, the pump gradually increases its speed to reach the temporary, lowered pressure setpoint (e.g., 15 psi). Once the system maintains this pressure for the duration of the step delay, the control system steps the setpoint upward by a designated amount (e.g., +5 psi, moving to 20 psi). The pump then ramps again to meet this new setpoint.

This process repeats—raising the pressure setpoint incrementally—until the system reaches the normal operating pressure. At that point, the station shifts back to normal operation, maintaining the standard pressure setpoint for ongoing operation. This controlled, stepwise approach prevents sudden pressure surges and reduces stress on downstream components during startup or low-pressure conditions.

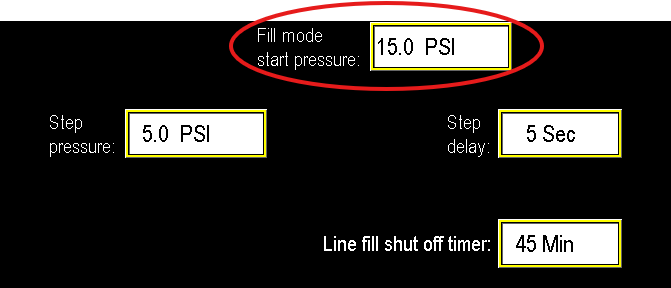

¶ Line fill shut off timer

The line fill shut-off timer (image 1.4) indicates the expected duration needed for the station to fill the line when fill mode is activated. Because each pump station varies, the time required to pressurize the system can differ; the key is to monitor how pressure builds during this process.

If the timer expires before the system reaches adequate pressure, the station will fault. If no pressure gains are observed, inspecting the discharge lines and pump station for leaks or blockages is recommended. Conversely, if pressure is gradually increasing but the timer times out prematurely, consider extending the timer to allow full pressure buildup during fill mode.